Computational Fluid Dynamic (CFD) software provides modeling of data center airflow and quick identification of hot spots. A CFD system’s three-dimensional, multi-colored thermal maps are downright sexy, and, if you’ll pardon the pun, extremely cool. When changes are made to the data center intentionally, CFD analysis can be repeated to detect the introduction of new thermal problems. So far, so good.

Computational Fluid Dynamic (CFD) software provides modeling of data center airflow and quick identification of hot spots. A CFD system’s three-dimensional, multi-colored thermal maps are downright sexy, and, if you’ll pardon the pun, extremely cool. When changes are made to the data center intentionally, CFD analysis can be repeated to detect the introduction of new thermal problems. So far, so good.

But what happens when the data center changes unintentionally? Today, CFD users require real-time thermal imaging of hot spots that could result from contingencies like equipment failure, blockage or cabinet overloading. Furthermore, users want more than just problem visualization – they want recommendations for problem mitigation. They want a CFD model with some muscle – in effect, a CFD on steroids.

But what happens when the data center changes unintentionally? Today, CFD users require real-time thermal imaging of hot spots that could result from contingencies like equipment failure, blockage or cabinet overloading. Furthermore, users want more than just problem visualization – they want recommendations for problem mitigation. They want a CFD model with some muscle – in effect, a CFD on steroids.

What is a CFD on Steroids, and more importantly, why do we need it?

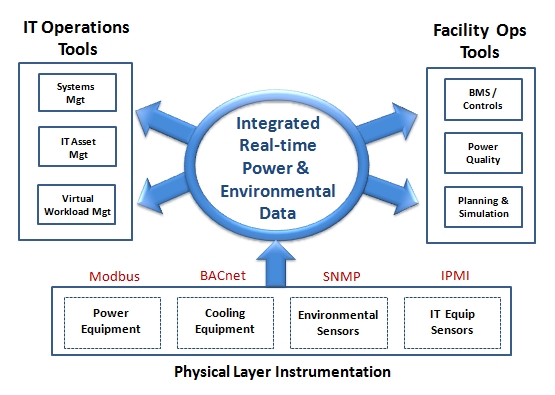

The CFD on steroids works in real-time by collecting and synthesizing all available sensor data within the data center. It leverages wireless, wired, server-based and return/discharge air-temperature readings to determine not only the immediate problem, but also the immediate impact. This high-fidelity monitoring system renders a thermal topology map and also sends immediate notification to operations personnel stating what temperature has been registered, where it is located, and that urgent action is needed.

Really pumping you up

The next level of growth in temperature control is temperature-based reaction. Data Center operators are now looking not only at identification but also action automation through demand-driven cooling directly to the cabinet. By leveraging Variable Frequency Drives (VFD) in cooling units, remote commands can adjust cooling at the point of demand. This can reduce power costs substantially and can prevent a cabinet meltdown. Automated actions can be taken with the existing Building Management System (BMS) without having to rip out and replace the entire system. Integration of CFD can make the BMS smarter - processing and synthesizing a vast array of data, encoding commands in building-management language, and passing reliable information to the appropriate destination so that the secure communication infrastructure can be fully maintained. Modius OpenData is currently being leveraged by customers to pump up their BMS, leverage the current infrastructure, prevent cooling related outages, and save money in power-related cooling.

The next level of growth in temperature control is temperature-based reaction. Data Center operators are now looking not only at identification but also action automation through demand-driven cooling directly to the cabinet. By leveraging Variable Frequency Drives (VFD) in cooling units, remote commands can adjust cooling at the point of demand. This can reduce power costs substantially and can prevent a cabinet meltdown. Automated actions can be taken with the existing Building Management System (BMS) without having to rip out and replace the entire system. Integration of CFD can make the BMS smarter - processing and synthesizing a vast array of data, encoding commands in building-management language, and passing reliable information to the appropriate destination so that the secure communication infrastructure can be fully maintained. Modius OpenData is currently being leveraged by customers to pump up their BMS, leverage the current infrastructure, prevent cooling related outages, and save money in power-related cooling.